6 steps to improve laser cutting quality of laser cutting machine

For newbies who are new to the laser cutting industry , they will encounter difficulties when they have poor laser cutting quality.to improve laser cutting quality is the first lesson for them.

How to improve laser cutting quality.

The following briefly introduces the problems and solutions to be encountered.

The parameters that affect the cutting quality are: cutting height, cutting nozzle model, focus position, cutting power, laser cutting Frequency, cutting duty cycle, cutting air pressure and cutting speed. The hardware conditions are: protection lens, gas purity,Plate quality, focusing mirror and collimator.

When the laser cutting quality is not good, it is recommended to carry out a general inspection first, and the main inspection content and sequence

Yes:

1 .cutting height (recommended actual cutting height is 0.8 ~ 1.2mm), if the actual cutting height is inaccurate,Calibration is required.

2. Cutting nozzle Check whether the cutting nozzle type and size are wrong. If it is correct, check whether the cutting nozzle is damaged.

Whether the roundness is normal.

3. It is recommended to use a cutting tip with a diameter of 1.0 for optical center inspection. The focus of the optical center should be -1 ~ 1.between. The light spots so small are easy to observe.

4. Protective lenses Check whether the protective lenses are clean and require no water, no oil, no residue. Sometimes because of the weatherOr the protective gas is too cold, which causes fogging of the protective lens.

5. Focus check, whether the focus is set correctly. If it is an autofocus cutting head, be sure to check whether the focus is correct.

6 .Modify cutting parameters

After all the above five items are checked and there are no problems, modify the parameters according to the phenomenon,to improvelaser cutting quality of laser cutting machine

How to adjust the parameters according to the phenomenon, the following briefly introduces the conditions encountered when cutting stainless steel and carbon steel

And solutions to improve cutting quality of laser cutting machine.

For example, there are many types of stainless steel slag. If only slag is hanging on the corner, the corner rounding should be considered first.

Aspects can reduce focus, increase air pressure, and so on.

If the whole slag is hanging, you need to lower the focus, increase the pressure, and increase the cutting nozzle, but the focus is too low or the pressure is too high.

The assembly resulted in delamination and rough surfaces. If the granulated soft slag is hung as a whole, you can increase the cutting speed or Reduce cutting power.

Cutting stainless steel may also encounter: slag hanging on the end of cutting, you can check whether the air supply

Insufficient gas flow cannot keep up.

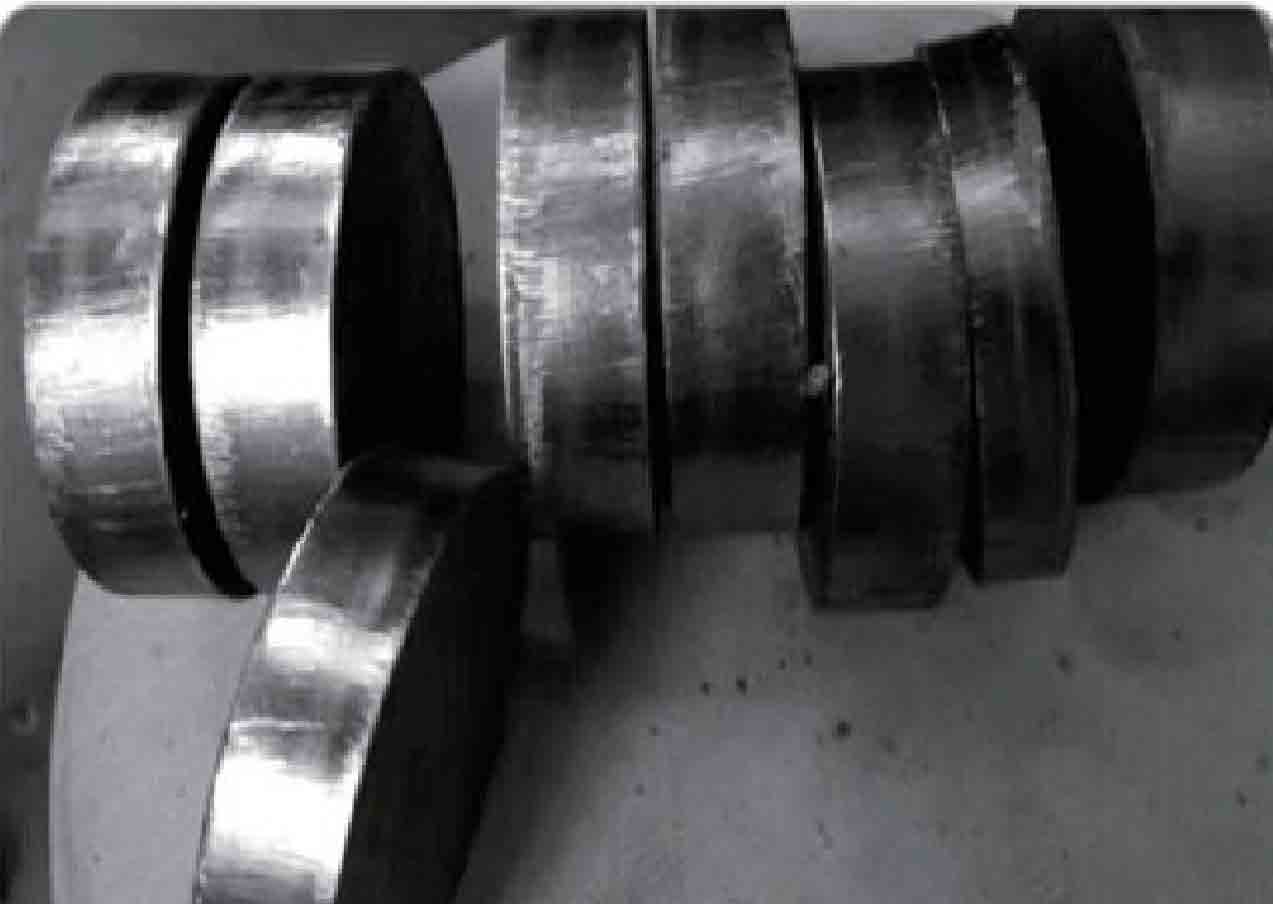

Cutting carbon steel generally encounters problems such as insufficiently bright sections of thin plates and rough sections of thick plates.

Generally speaking, a 1000W laser can cut the light of no more than 4mm carbon steel. 2000W is 6mm and 3000W.

It’s 8mm.

If you want to cut the light of the cross section, first of all, the board must have a good surface without rust, no paint, and no oxide scale.

It must be at least 99.5% higher. When cutting, you need to pay attention to the following: use a small cutting nozzle to double or 1.0, the cutting speed needs to be more than 2m / min, and the cutting pressure should not be too high.

If you want the quality of the thick plate cutting section to be good, you must first ensure the purity of the plate and gas, and then the selection of the cutting nozzle.

The larger the hole diameter, the better the section quality, but at the same time the section taper will be greater.

If you want to cut bright, you must first have a good surface with no rust, no paint, no oxide scale, and secondly, the purity of oxygen should be at least 99.5% or higher. The cutting needs to pay attention to: double-layered with a small cutting nozzle 1.0 or 1.2, the cutting speed It needs to exceed 2m / min, and the cutting pressure should not be too high.

If you want the quality of the thick plate cutting surface to be good, you must first ensure the purity of the plate and gas, and then the selection of the cutting nozzle.The larger the hole diameter, the better the cutting quality, but at the same time the cutting taper will be bigger.

to improve laser cutting quality is meaningful and economical,Ensure a good cutting section effect, save the grinding process, and save materials and labor to the greatest extent。if you know more proctic informations of how to improve laser cutting quality,welcome to discuss more .