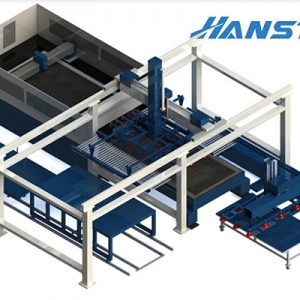

New Han-SG1600 Metal Grinding Deburring Edge Rounding and Finishing Machine Specifications

Metal Finishing Machine description:

HAN-SG1600 is a multipurpose machine used for the flat sheet metal cutting or punching parts grinding, deburring, edge rounding and surface or Hairline finishing etc.

The operations stations consist of one wide belt grinding station for deburring, one planetary type abrasive strip roller brushing station for deburring and edge rounding, one wide belt grinding station for surface No.4 finishing and one barrel scotch brite brushing station for Hairline finishing.

Each station can be operated independently or used together.

This is a dry type operation machine, should be work with a dust collector.

2、Technical data sheet OF Deburring Machine

2.1 Max.working width:1000mm

2.2 Working thickness: 0.5-100mm

2.3 Min. working size: 50x50mm

2.4 Feed speed: 0.5-5m/min variable speed

2.5 Speed of whole head rotation: 0-9.6r/min variable speed

2.6 Speed of brush spindle:0-1575r/min variable speed

2.7 Number of abrasive cylinders: 6

2.8Size of abrasive cylinder: Φ300mmx290mm

2.9.Size of wide belt: 1030x2200mm

2.10Dust extraction: 4000m3/h

2.11Total power: 24.62KW

2.12Weight: 3500KGS

2.13 Machine size:2200X2050X2400mm

Metal Finishing Machine main parts:

Station 1: Wide belt grinding station

Function: Used for big burrs, big laser cutting spot removal.

Station 2: Planetary flexible abrasive strip brushing system

Function: Deburring and edge rounding, can also do the plastic film parts deburring.

Station3: Wide belt grinding and finishing station.

Function: Surface hairline finishing after deburring and edge rounding.

Station 4: Barrel brush hair line finishing station.

Function: Surface hairline finishing.

Staion 5.Feed table and dust collector:

Metal Finishing Machine Main parts list:

| Part name | Specification | QTY | Marks |

| Conveyor belt | 7938X1600mm

(vacuum belt) |

1 | For feed |

| Contact roller | Ф185×1600mm

Rubber shore: 65+45shore |

2 | For abrasive belt grinding |

| Barrel brush | Ф200×1600mm grit120 | 1 | For barrel brush station |

| Brush drive motor | 15KW | 1 | For barrel brush |

| Speed reducer | NMRV90-100-Y(3KW-6)-V6 | 1 | For feed |

| Motor | 3.0KW-4 | 1 | For feed drive |

| Lift machine | WPDX060 | 1 | For abrasive cylinder lift |

| Lift motor | 1.5KW | 1 | Abrasive cylinder lift power |

| Vacuum pump | 15 KW | 1 | For vacuum generator |

| Motor | 18.5KW-4 | 2 | For abrasive belt drive |

| Motor | 2.2KW | 4 | For abrasive strip brushes drive |

| Inverter | 1.5KW DELTA BRAND | 1 | Assembly speed |

| Inverter | 3.7KW DELTA BRAND | 1 | Feed speed adjust

|

| Inverter | 11KW DELTA BRAND | 1 | Abrasive cylinder

Speed adjust |

| Touch screen PLC | MITSUBISHI brand | 1 | For control and display |

| Low electrical parts | Schneider | 1set | For control |