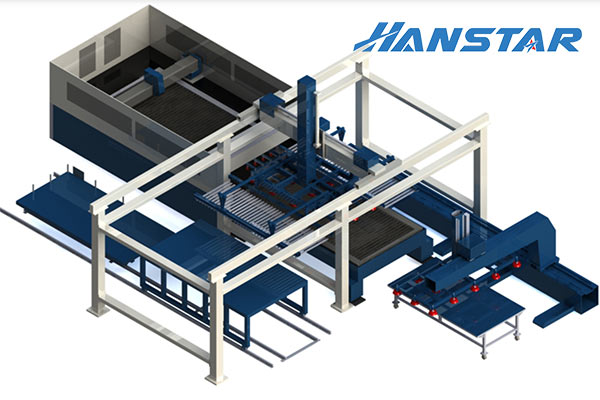

Automatic Loading Unloading Machine For Laser Cutting Machine

Product introduction of automatic laser loading unloading machine

Fully automatic laser loading and unloading machine (laser feeding robot) can cooperate with various types of laser cutting machines of different sizes to realize automatic feeding of metal plates, automatic separation of finished products and waste, and the production is more economical and safe. It is conducive to realizing automatic operations such as sheet metal plate transmission and feeding, improving production efficiency and reducing production costs. In the case of high and low temperature, dust, noise, radiation, and narrow space, manual feeding and direct operation are not only dangerous, but also costly and inefficient.

Fully automatic laser loading and unloading machine, especially suitable for factories with large cutting volume and many repetitive workpieces.

Advantages of automatic laser loading unloading machine

The sheet metal processing industry is equipped with a fully automatic laser loading and unloading machine, which can reduce manpower and control the production rhythm more accurately. It is an inevitable trend for enterprises to increase production capacity, reduce production costs, and save labor.

The fully automatic laser loading unloading machine produced by our company adopts the modular design of intelligent laser feeder, which is compact in design and can save the required production workshop area. It can be used with various laser cutting machines. we can design machine according to customer’s request.

1·Intelligent detection

Prevent multiple sheets from being loaded at the same time during operation

2·Digital work

Safe handling to prevent scratches on the board and bring better quality of finished products

3· No need for manual guarding

Equipped with remote monitoring function, real-time grasp of machine operation

The whole process, fully automatic and efficient collaboration, has the advantages of optimizing the production process, reducing equipment standby time, reducing labor costs, improving site utilization, and improving production efficiency. It provides customers with a one-stop complete solution for laser cutting and intelligentizes the enterprise workshop. , digital upgrade to pave the way.

Technical parameters

of automatic laser loading unloading machine:

| Item | In | Parameters |

| plate thickness | mm | 1-8 |

| Max plate size | mm | 3000×1500 |

| minimum plate size | mm | 1250×1250 |

| max plate weight | KG | 300 |

| Horizontal movement maximum moving speed X axis | M/MIN | 30 |

| Vertical movement maximum moving speed Z axis | M/MIN | 12 |

| X-axis travel | mm | 5000 |

| Z-axis travel | mm | 900 |

| Maximum speed of gear shaping operation | M/mm | 15 |

| The maximum load of the truck | KG | 3000 |

| Maximum moving speed of material cart | M/mm | 12 |

| Gas | Mpa | 0.55 |

|

Dimensions of loading and unloading robot |

Length / mm | 7000 |

| Weidth /mm | 4300 | |

| Height/mm | 4600 |