When more and more customers feel that your price is expensive the first time they get your quotation, as a worker who has been working in the laser industry for 10 years, I will always feel unspeakable disappointment in my heart.

So, what is the main reason?

Language is pale, so let’s briefly explain it with pictures.

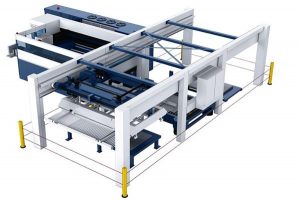

1.The first big difference is on the machine bed structure.

(picture A,)a normal laser cutting machine

The above photo is of a typical laser cutting machine made in China. Its exquisite appearance seems to be no different. But let me open its cover and let you see its internal structure!

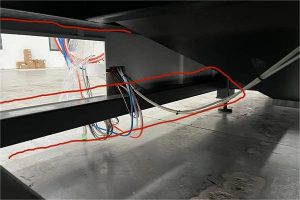

inside metal bed structure of cheap laser cutting machine

After taking off the outer cover, you can see that the bed inside is just two tubes, not even a triangular structure.

As shown in the picture above, when you open the sheet metal cover of the laser cutting machine, you will see the machine tool frame inside. Like this super cheap laser cutting machine, its bed is only composed of two square tubes(with red mark),which is very funny.

Obviously, this kind of lathe will not undergo stress relief hot treatment. Because fading will deform the thinner tube.

The serious consequence is that the machine tool will deform after being used for a period of time, thereby losing cutting accuracy.

Secondly, the weight of this machine tool bed itself is very light. Take the 3015 single table as an example, it is 600kg. The machine tool is not heavy enough and the load-bearing capacity is relatively light. If thick plates are cut for a long time, the bed will deform and even crack at the welds.

As shown in the picture above, this is a machine tool produced by our company.

Built with10 mm thick steel offers good rigidity and high strength;

The bed is welded and meticulously machined followed by PWHT- stress relief ensures no structural deformation;

12 hours of PWHT

to eliminate welding stress

Lasts for > 20 years without deformity

Above Picture of Cheap Bed

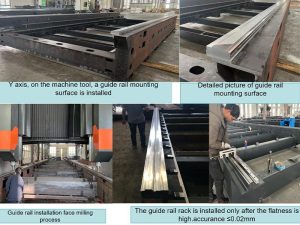

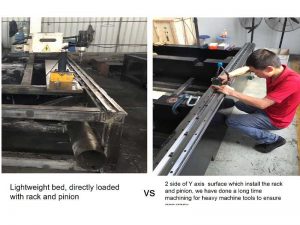

2.Milling accuracy of machine bed

Another important point is that almost all of this kind of cheap bed structure have the guide rails and racks directly installed on the pipes of the side of the machine tool. The pipes on the side have not been processed by a milling machine. So the mounting surface of the guide rails and racks is not flat, It will lead to low accuracy and poor stability of the machine.

As shown in the figure above, this cheap machine saves labor and processing time. It directly installs the guide rail and rack on the square tube on the side of the machine tool without milling. In this way, the accuracy of the machine will be reduced.

The second difference ,IS the crossbeam of the machine tool.

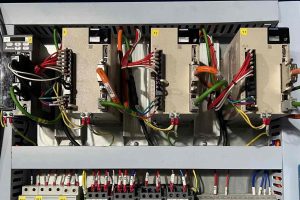

This kind of thin, slim machine tool beam made of bent steel plates or aluminum profiles greatly reduces material costs and turning and milling costs. Its disadvantage is that it cannot withstand high speeds, so next you will see, as shown in the picture below, that the motor it is equipped with is 0.4kw. Yes, you read that right, four unit 0.4kw motors.

4 unit 400w motor for both x and y axis

400W Motor

The y-axis also uses a 400w motor. If the seller tells you that this machine is a high-speed, stable machine, then it must be lying. Even if he shows you that the speed on the CNC software on the machine is 1.0g, it is still false. Because most of these CNC software can change the data by the factory itself.

Speaking of which, our standard machine is a 1.8kw motor. High-end machines use 3.6kw motors. This is also a detail that determines whether your machine is a high-quality machine.

Our Standard Machine Are 1.8kw Motors

Regarding the brand of motor, our standard machine uses Yaskawa from Japan. Of course, if customers strongly demand a more economical Delta, it is also a good choice. At least 1.5kw.

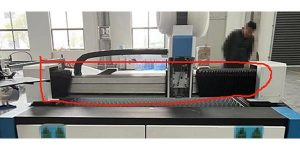

one piece cast aluminum beam

we used One-piece cast aluminum beam. Cast aluminum achieves the lightest weight when stability is required, so that the machine tool can still run stably without shaking even when it reaches 1.5G acceleration. The one-piece beam can ensure that the beam remains stable and does not shake during high-speed movement.

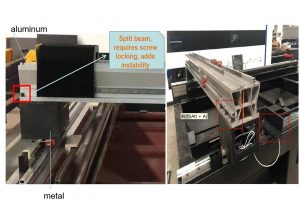

Split beam pictures

As shown in the picture above, the split beam is fixed by several screws. The beam of the laser cutting machine needs to move at high speed frequently. Over time, the screws will loosen, which will affect the cutting accuracy. At this time, it may appear that the cutting straight line turns into a diagonal line.

Regarding the cross beams, there are also differences between iron cross beams, aluminum cross beams, cast aluminum cross beams, and brushed aluminum cross beams. The cross beams also have different thicknesses. These are all factors that affect the price.

The difference of components

Apart from the machine tool part, another major factor affecting the price is the brand of the various components that make up the machine.

Just like our computer, it is composed of some core components (CPU, hard disk, motherboard, etc.). The main components of the laser cutting machine are laser, chiller, cutting head, control software. The brand and model of these components directly affect the price of the laser cutting machine.

In addition, the transmission parts, such as motors, reducers, guide rails, racks, etc., have different brands and models, and the prices vary greatly. First-tier brands are preferred, such as Japanese and German brands, and second-tier Taiwanese brands. There are also many Chinese brands, and the prices are very cheap.

It should be noted that many German and Japanese brands are counterfeit products from China and are not genuine. They usually use crude technology, such as using a marking machine to stamp the YYC brand, which can save $1,000 on a machine.

The above picture is a comparison of the real and fake YYC. The left is fake. The Chinese factory used its own marking machine to mark YYC letter, which saved costs to the greatest extent. This imitation is relatively rough, which can be seen from the color of the marking and the rough teeth of the rack.

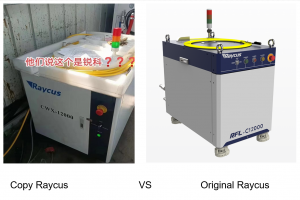

As shown in the picture above, even the core component laser has copies. There are also some old lasers that are refurbished.In addition, there are CNC systems and cutting heads. Different brands have very different prices. These can be customized at will, using unknown and poorly functional ones and branding them with their own company’s brand.

In summary, the differences in various aspects have caused a huge gap in the overall price of the machine. Too many customers asked me why the price of the machine is so different? The same model? The same configuration? So I wrote this article to make a comprehensive analysis. Thank you for watching.