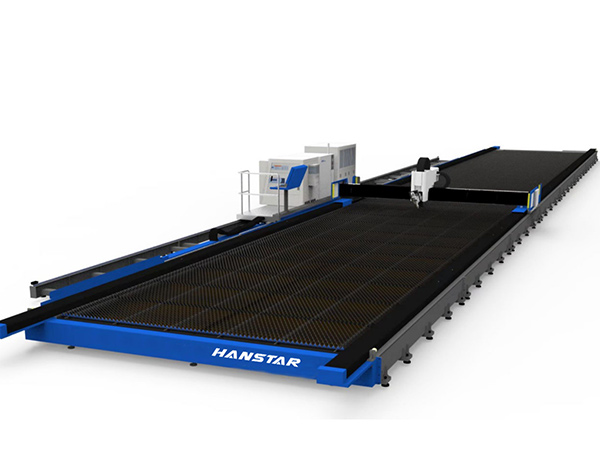

HSF-1325G Ground Rail 12KW-40KW High precision heavy duty cnc laser cutting machine

- Application Industy:Suitable for cutting space: two-dimensional plane cutting;

- Application industries: sheet metal processing, rail transit, shipbuilding, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, tool processing, petroleum machinery, Various machinery manufacturing and processing industries.

- Cutting material: carbon steel, stainless steel, aluminum alloy, brass, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, nickel plate and other metal materials.

- Cutting range: 0.5~60mm carbon steel, 0.5~40mm stainless steel, 0.5~50mm aluminum alloy, 0.5~20mm brass.

Cnc Laser Cutting Machine HSF-1325G Technical Details :

| Precision(cnc laser cutting machine) | |

| X, Y motion positioning accuracy | 0.08mm/m |

| X, Y axis motion repeatability | 0.05mm/m |

| Processing format and working range(cnc laser cutting machine) | |

| X, Y axis working stroke | 13000mm×2500 mm |

| X-axis travel | 13000mm |

| Y-axis travel | 2500mm |

| Z-axis travel | 300mm |

| Speed | |

| moving speed | 80m/min (guarantee the stability of the machine tool) |

| acceleration | 1.0G |

| Voltage | |

| Operating Voltage | Three-phase 380v/50Hz |

| total machine weight | 32 tons (Based on 1325model size ) |

| Laser performance parameters | |

| Transmission fiber diameter | 100μm |

| central radiation wavelength | 1080nm |

| cuttable material | cnc laser cutting machine can cut Stainless steel, carbon steel, aluminum, brass, copper, manganese, nickel other metal materials |

General diagram of motion system of cnc laser cutting machine

The machine tool kinematic system is mainly divided into two parts, one is the movement of the beam, and the other is the movement of the Z-axis part.

The beam of this equipment is made of aluminum alloy profiles, which has high structural strength and good tensile strength, so as to ensure better dynamic performance of the beam.

(1) The cast aluminum beam is used for rough machining after annealing to eliminate internal stress, and then finished after secondary vibration aging treatment, which ensures the overall strength, rigidity and stability of the beam. The weight per meter is about 80KG. The top and side of the beam is an external organ cover closed structure, and an organ protective cover is also installed between the beam and the lateral sliding plate to ensure the tightness and dust resistance of the rack and the linear guide.

With a patented design, one-piece cast aluminum beam

(2) Motion system design features

a)The space is compact and the structure is reasonable. The reducer and the motor are all designed behind the moving plate (slide), and the gear rack and pinion gear components are all designed in the sliding plate, and the structure is very compact. In addition, a dust cover is designed at the bottom of the sliding plate, because laser cutting belongs to metal cutting, and there is a lot of metal dust.

If the moving part is not dust-proof, the meshing of the gears and the movement of the cross guide will be quickly caused by the entry of metal dust particles. The wear and tear greatly affects its service life. Therefore, the dust cover is designed at the bottom, which has a great direct dustproof effect, ensuring that the guide rail will not be seriously worn due to the entry of metal dust particles between the moving parts, and improving the accuracy and service life.

b)The movement speed is fast and the acceleration is high. Because the power of the laser cutting machine is getting higher and higher, the movement speed of the machine tool is getting faster and faster. Therefore, the response speed of the sliding plate installed with the cutting head must be fast, otherwise it is easy to cause the cutting head to move slowly due to the slow movement of the sliding plate. It collides with the steel plate, so the Z-axis moving body adopts rack and pinion transmission, and its moving speed can reach up to 35 m/min, that is, 1.7 m/s.

The movement stroke of the sliding plate is 220mm, and it takes less than 0.5 seconds to lift the sliding plate from the lowest surface to the very top to avoid collision. In addition, the acceleration of the sliding plate during movement can reach a maximum of 2G, which can ensure that the speed is increased to the maximum in an instant.

Cutting Samples of cnc laser cutting machine :