High Power best 8000W 12000W 15000W 20000W CNC exchange bed full enclosed industrial laser cutting machine HSF-3015HP

Application industries:

Industrial Laser Cutting Machine HSF-3015HP ,sheet metal processing, rail transit, shipbuilding, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, Various machinery manufacturing and laser external processing services.

- Cutting material:carbon steel, stainless steel, aluminum alloy, brass, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, nickel plate and other metal materials.

- Cutting range: 0.5~40mm carbon steel, 0.5~40mm stainless steel, 0.5~30mm aluminum alloy, 0.5~16mm brass.

Technical Parameters of industrial laser cutting machine:

| Precision | |

| X, Y motion positioning accuracy | 0.03mm/m |

| X, Y axis motion repeatability | 0.03mm/m |

| Processing format and working range | |

| X, Y axis working stroke | 6000mm×2500 mm/6015/6020 customized |

| X-axis travel | 6020mm |

| Y-axis travel | 2520mm |

| Z-axis travel | 300mm |

| Speed | |

| moving speed | 120m/min (guarantee the stability of the machine tool) |

| acceleration | 1.5G |

| Voltage | |

| Operating Voltage | Three-phase 380v/50Hz |

| total machine weight | 26 tons (Based on 6025size )

32 tons (Based on 9025size ) |

| Laser performance parameters | |

| Transmission fiber diameter | 100μm |

| central radiation wavelength | 1080nm |

| cuttable material | Stainless steel, carbon steel, aluminum, brass, copper, manganese, nickel other metal materials |

4.Others size of industrial laser cutting machine

| Machine Model | HSF-3015HP | HSF-4015HP | HSF-6015HP | HSF-4020HP | HSF-6020HP |

| Cutting Size | 3000×1500 | 4000×1500 | 6000×1500 | 4000×2000 | 6000×2000 |

| Machine Model | HSF-6025HP | HSF-8025HP | HSF-9025HP | HSF-1025HP | HSF-1225HP |

| Cutting Size | 6000X2500 | 8000X2500 | 9000X2500 | 10000X2500 | 12000X2500 |

Areas of Use and Capabilities of industrial laser cutting machine:

- Suitable for cutting space: two-dimensional plane cutting;

- Application industries: sheet metal processing, rail transit, shipbuilding, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tool processing, petroleum machinery, food machinery, kitchenware and bathroom, Various machinery manufacturing and processing industries such as decorative advertising and laser external processing services;

- Cutting material: high carbon steel, low carbon steel, stainless steel, aluminum alloy, brass, pickling plate, galvanized plate, silicon steel plate, electrolytic plate, titanium alloy, manganese alloy, nickel plate and other metal materials.

- Cutting thickness range: 0.5~40mm carbon steel, 0.5~40mm stainless steel, 0.5~30mm aluminum alloy, 0.5~16mm brass.

Advantages of Industrial Laser Cutting Machine :

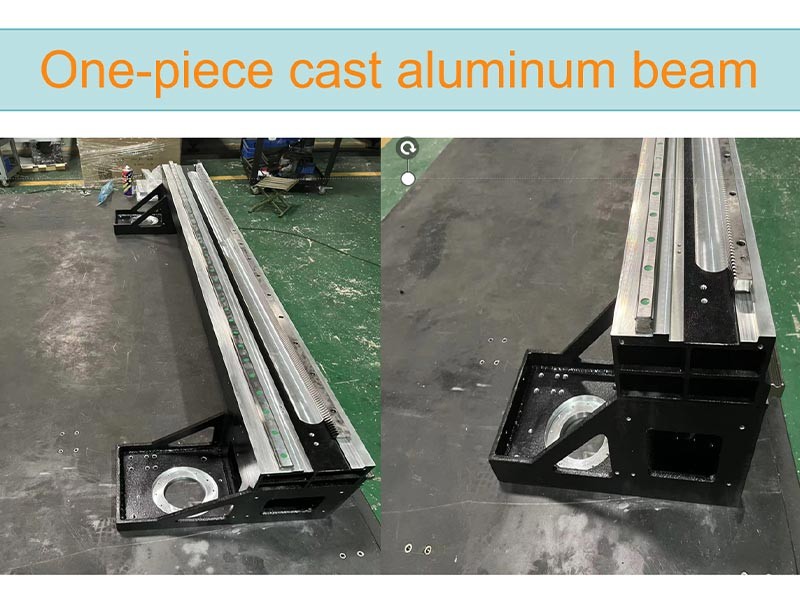

1..One-piece cast aluminum beam.

Cast aluminum achieves the lightest weight when stability is required, so that the machine tool can still run stably without shaking even when it reaches 1.5G acceleration. The one-piece beam can ensure that the beam remains stable and does not shake during high-speed movement.

As shown in the figure 2 below, the beam (from other china supplier)is only connected with the machine tool by screws, and the machine tool will loosen when it runs, affecting the cutting accuracy.

2.Industrail laser cutting machine head Aluminum mounting slider

laser Cutting head Aluminum mounting slider Aviation aluminum extruded slider is light in weight, high in hardness, and easy to adjust, ensuring smooth running of the slider, reducing mechanical friction, no noise during movement, and extending its service life.

We have installed automatic lubricating oil for the slider, which can effectively prevent mechanical wear。

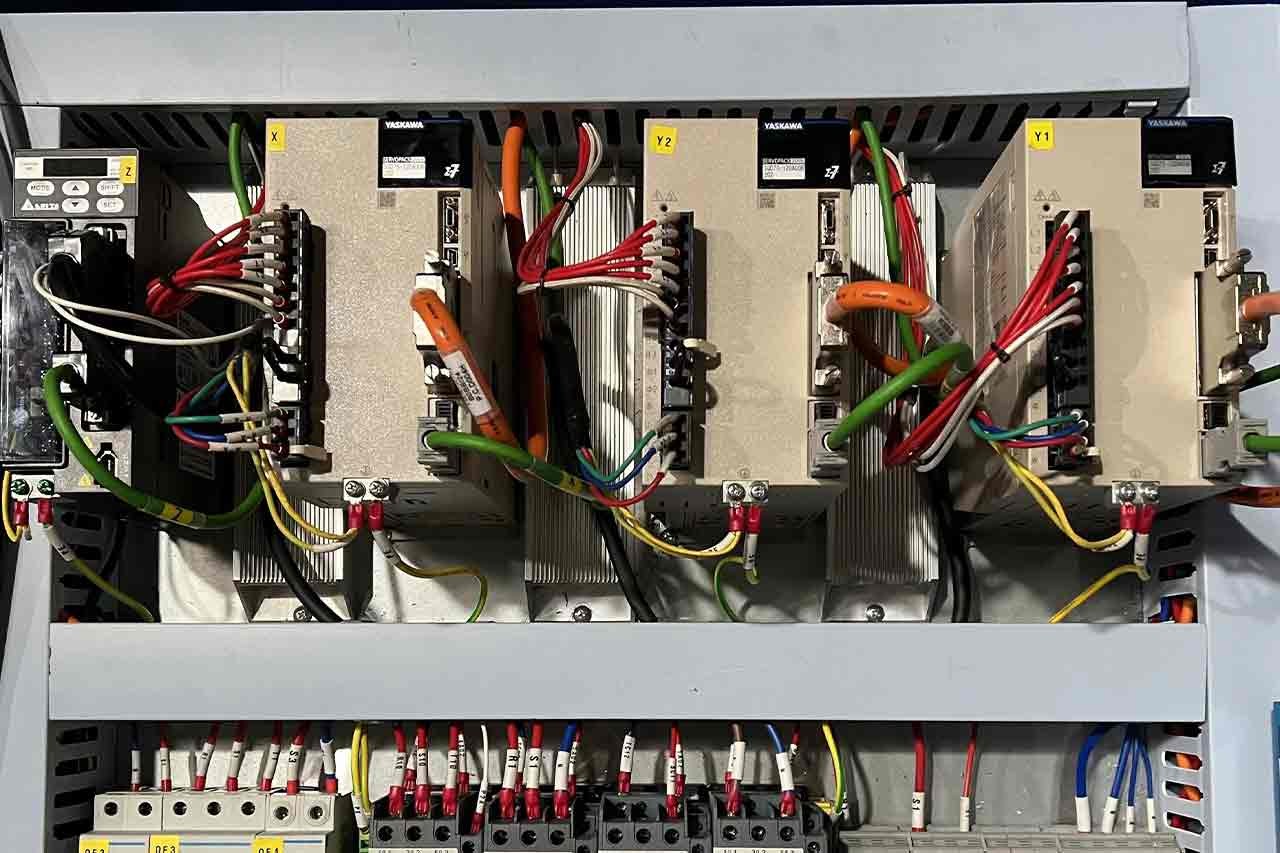

3.Industrail laser cutting machine with Simple, clear circuit routing, more convenient maintenance 2.Electric control cabinet equipped with air conditioning to ensure that the electrical appliances work more smoothly under high temperature conditions in summer

4.Industrail laser cutting machine with fast high cutting speed .

Travel speed 90meters /minutes,with an Real 1.5G acceleration speed at cypcut system ,at an travel low -pass frequencey 6hz with an cutting low -pass frequency 5hz .Machine runs stably without shaking,1-3kw bed ,4kw-6kw bed 1kw-6kw open table ,laser source power optional .

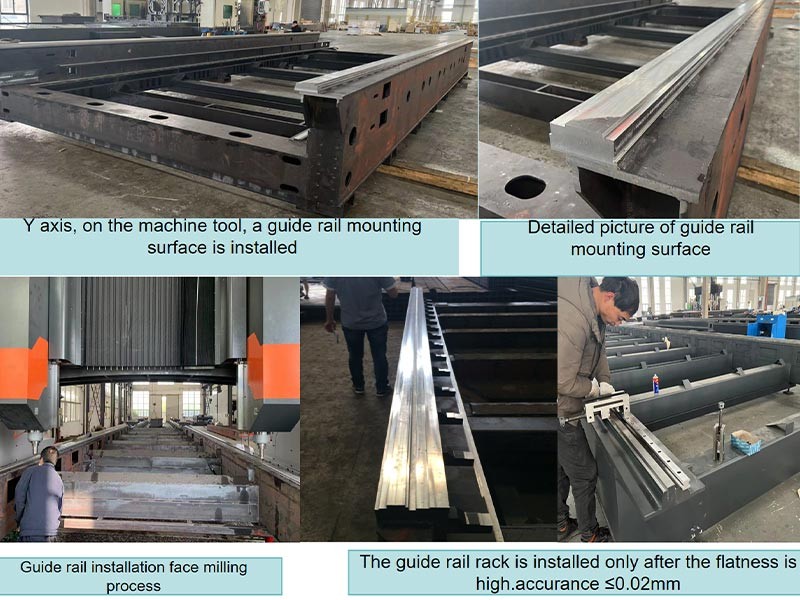

5.Sheet Metal welding bed

Continuing the structure of internationally famous laser manufacturers TRUMPF and Farley Laser, the whole machine body is welded with 25mm thick steel plate, and the inside of the machine body is filled with small square iron plates, which has good stability, good rigidity and high strength.After the bed is welded, PWHT heat treatment is performed to relieve stress and ensure that the structure is not deformed.

And a good dust removal system has been established to ensure that all smoke and dust generated during cutting are removed. And insulation protection has been added to ensure that the machine tool will not be damaged or deformed by laser even after long-term cutting.

Industrial Laser Cutting Machine HSF-3015HP Cutting Samples: