Handheld laser cleaning machine use safety knowledge:

(1) For the safety of you and others, it is strictly forbidden to point the cleaning head at yourself or others;

(2) Appropriate and certified 1080nm near-infrared band laser protective glasses must be worn before using the handheld laser cleaning machine;

(3) The operation of the handheld laser cleaning machine must be carried out in an independent space with laser protection; non-operating personnel and combustible and combustible materials should be kept away from the cleaning operation table for more than 10 meters, and a fire extinguisher should be placed near the cleaning area;

(4) Make sure that the grounding of the hand-held laser cleaning machine is normal, otherwise it may cause the product shell to be electrified and cause personal injury to the operator; if the grounding is not performed according to the requirements, it may cause hidden faults such as laser alarm, no light, and laser instability;

(5) Do not work outdoors in a rainy environment, otherwise it may cause a short circuit, affect the normal use of the equipment, and even cause safety hazards.

laser protection for laser cleaning machine use safety knowledge

(1) The operator of the laser cleaning machine or the person who is close to the laser equipment at work should wear suitable protective glasses and protective clothing.

(2) If combustible or combustible materials are close to the cleaning area, the heat and sparks generated during cleaning may cause fire or explosion. Fire extinguishers should be located nearby and within easy reach.

(3) Exposure to infrared and ultraviolet radiation during cleaning can damage the skin. Infrared and ultraviolet light can cause skin burns, increase welders’ risk of skin cancer and accelerate signs of skin aging. Cleaning sparks can also cause burns. Take precautionary measures, wear protective clothing.

(4) When cleaning, please keep your head away from the smoke. Always wash in an area that is well ventilated so the air is safe to breathe.

Electrical Safety for laser cleaning machine use safety knowledge

(1) Please ensure that the equipment shell is well grounded, any interruption in the grounding loop may cause personal injury;

(2) Before using the power supply connected to the device, please confirm that it has been connected to the protective ground;

(3) In order to reduce the risk of fire, when necessary, the replacement line fuse can only be of the same type and level, and other fuses cannot be used or material instead;

(4) Make sure that the input AC voltage of the hand-held laser cleaning machine is the normal AC mains voltage (single-phase voltage 200-240VAC), and the wiring is correct. Any wrong wiring method may cause personal injury or equipment damage;

Safety precautions for laser cleaning machine use:

It is strictly forbidden to operate laser equipment after drinking or fatigue;

▷ Turn on the machine and check whether there is any abnormality in operation;

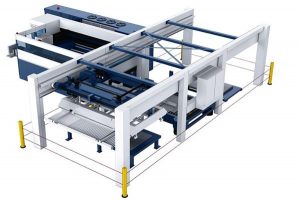

▷ Turn on the robot and laser strictly according to the operating instructions, and check whether the robot and laser are working normally (for cleaning machines with robot arms);

▷ Do not process materials that do not know whether they can be processed by laser, so as to avoid danger to operators and equipment;

▷ Please observe whether there are people in the working area and the operating area of the workbench before the equipment is in operation, so as to avoid injury;

▷ New workpieces must be tested and their operating status checked;

▷ When the equipment is in operation, the operator needs to pay close attention to the cleaning situation, and is not allowed to leave the post without authorization or leave it to someone to be managed. If it is really necessary to leave, the operator should stop the machine or cut off the power switch.