New ceramic Laser cutting machine HSF-6060P Features:

Cutting Materials:

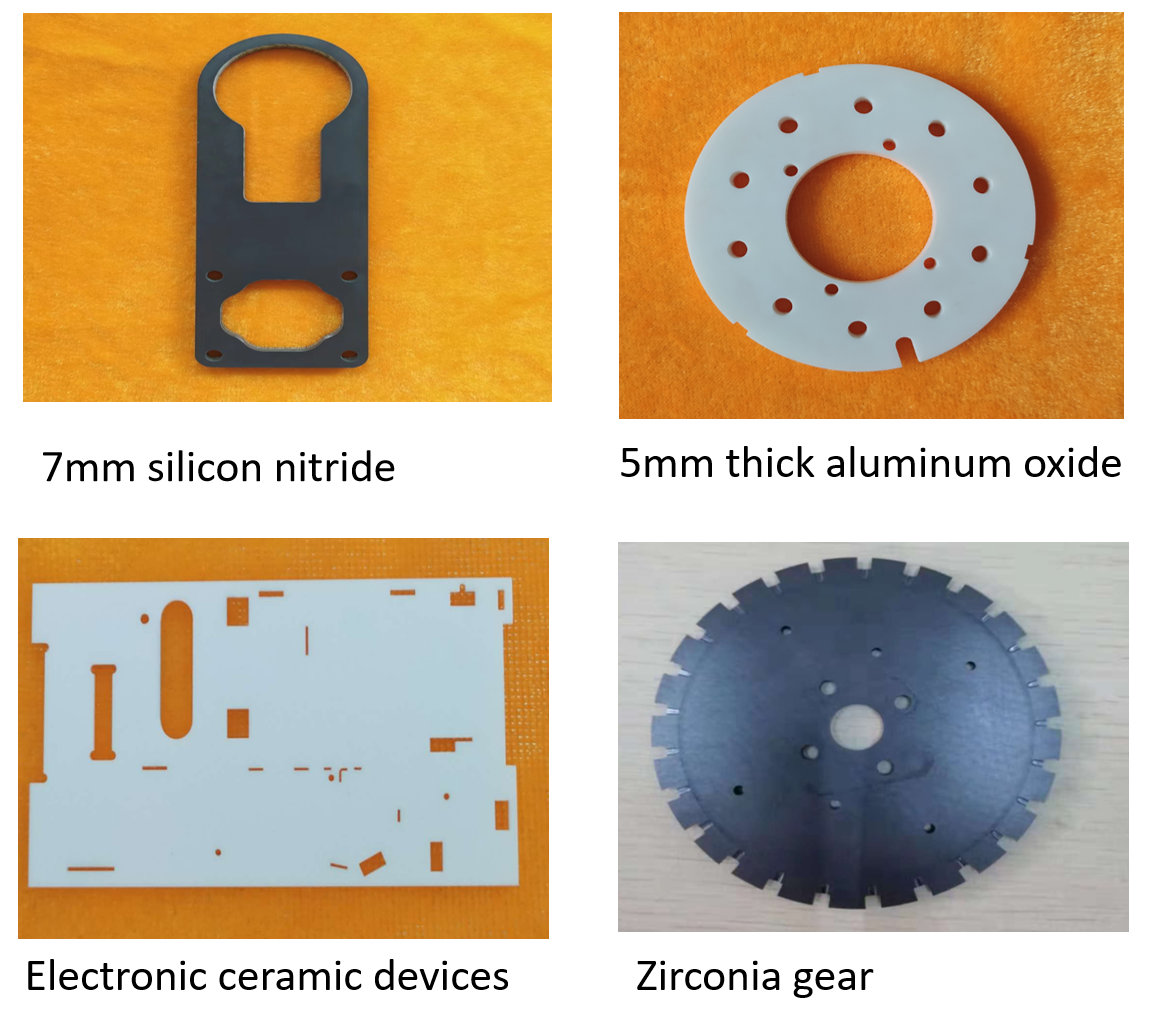

※Mainly used for laser cutting and drilling of advanced ceramics such as alumina, zirconia, aluminum nitride, silicon nitride, etc.

※With the CCD visual positioning system, it can also be used for cutting and scribing of metallized ceramics and chip substrates.

※It can also be used for high-precision laser cutting of medical equipment, military products, aerospace and other precision products.

Suitable Working Industry of small ceramic laser cutting machine HSF-6060p

Industrial products: various industrial ceramic accessories and molds

PCB industry: cutting, drilling and scribing of copper-aluminum substrates and ceramic circuit boards.

New energy industry: solar photovoltaic equipment, automotive sensors, hydrogen fuel cells and other ceramic devices.

3C industry: ceramic substrates, mobile phone ceramic back panels, middle frames, e-cigarette heating sheets, ceramic fingerprint recognition covers, etc.

Our small ceramic laser cutting machine hsf-6060p technical short introduction:

1. 600℃ heat treatment, 24 hours cooling in the oven, 8 meters gantry milling machine processing, precise CO2 protection welding, to make sure 20 years usage without deformation.

2. Precise collimator used for guide rail assembling and debugging, precision is up to 0.02mm.

3. German precise guide rail and ball screw transmitting.

4. Equipped with Japanese Sanyo inertia servo motor, high transmitting precision.

5. Fully closed protective cover.

Advantage of small ceramic laser cutting machine HSF-6060P

1. It adopts marble precision platform and gantry integrated closed structure, which has good rigidity, shock resistance and high-speed stability;

2. It adopts imported magnetic levitation linear motors, high-precision guide rails and 0.5um high-precision grating ruler fully closed-loop feedback system, with fast speed, high precision and low maintenance rate;

3. Use special fiber lasers and precision special cutting heads to ensure small cutting slits, high precision, and smooth cutting surfaces without burrs;

4. Built-in power regulator, safety protection equipment and electrical appliances, stable and reliable;

5. CCD automatic positioning system and visual lens can be configured as needed, which can accurately identify various Mark points;

6. The self-developed cutting software is easy to learn and use, and customers can choose customized functions.

Usage: Mainly used for laser cutting and drilling of precision ceramics such as alumina, zirconia, aluminum nitride, silicon nitride, etc.

Main parts configuration of Small ceramic Laser Cutting Machine HSF-6060P

1.Adopt Japanese THK precision linear guide rail, with high positioning accuracy and less wear; it can maintain high precision for a long time, easy to assemble and interchangeable.

2.EtherCAT bus-type AheadTechs numerical control system (AheadTechs), which greatly improves the flexibility and scalability of the equipment. Make smart factories and equipment interconnection possible.

3.Support multiple modes of axis pitch compensation to ensure the machining accuracy of the machine tool.

4.Support parts processing statistics and production quantity management.

Technical details of small laser cutting machine :

| small laser cutting machine : | ||

| security function | laser unnormal alarm | yes |

| cutting unnormal alarm | yes | |

| gas low pressure alarm | yes | |

| door lock alarm | yes | |

| water chiler temperature unnormal alarm | yes | |

| Total power | 500w laser cutting machine | 7kw |

| 1000w laser cutting machine | 8kw | |

| laser source | fiber laser | |

| Laser power | 500W/1000W | |

| Table size | 600x600mm | |

| Max speed | 1.5G | |

| Cooling way | water cooling | |

| Laser wavelength | 1070nm | |

| Min. cutting gap | ≤0.1mm | |

| Max moving speed | 80m/min | |

| Repeated positioning accuracy of X, Y and Z axles | ±5um | |

| Working temperature | 5℃-45℃ | |

| Power requirement | 380V,50/60Hz(customized for you) | |

| Continuous working time | 24 Hours | |

Ceramic Cutting Samples :

ceramic laser cutting

ceramic laser cutting