Small Laser cutting machine HSF-6040P Features:

Cutting Materials:small laser cutting machine HSF-6040P can cut Mild steel, stainless steel, aluminum alloy, brass, copper, pickling plate, galvanized plate, silicon steel, electrolytic plate, titanium alloy, manganese alloy.

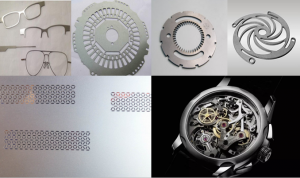

Suitable Working Industry of small laser cutting machine HSF-6040p

Jewelry, glasses, lighting, kitchen and bathroom products, mobile communications, digital products,

Electronic components, clocks, computer accessories, instruments, precision devices

Our small laser cutting machine hsf-6040p technical short introduction:

1. 600℃ heat treatment, 24 hours cooling in the oven, 8 meters gantry milling machine processing, precise CO2 protection welding, to make sure 20 years usage without deformation.

2. Precise collimator used for guide rail assembling and debugging, precision is up to 0.02mm.

3. German precise guide rail and ball screw transmitting.

4. Equipped with Japanese Sanyo inertia servo motor, high transmitting precision.

5. Fully closed protective cover.

Advantage of small laser cutting machine HSF-6040P

1. This machine is mainly for high-speed laser processing of thin plates. The whole machine runs stably, the technology is mature, and the cutting efficiency is high. It covers an area of about 1800*1430. Full-time cutting, high-efficiency cutting, high-quality cutting, and high material utilization rate , highly scalable and very flexible.

2. The main machine of the equipment has good overall rigidity and high strength. The base is made of blue marble, and the beam is made of extruded aluminum profiles, which have good acceleration performance and effectively prevent structural deformation.

3. The weight of the equipment is about 1.5T .With the fully enclosed sheet metal cover, the weight of the whole machine reaches 2.0ton. It ensures that the machine still maintains precision and no vibration when cutting at high speed.

4. Visual processing positioning configuration (optional), 5 million pixels, 14fps, with frame memory, Gigabit Ethernet interface. The visual inspection system uses software to process images. The software employs algorithmic tools to help analyze the images. Use the visual camera to complete the search for mark points.

Sampling is carried out, and the sampling is completed to locate the mark point. Processing according to the group After the graph is processed, you can adopt processing and non-processing methods for the currently set group. The group that needs to be processed is currently set to be processed, and the group that does not need to be processed is set to be not processed. Effectively avoid thermal deformation accuracy errors caused by cutting.

Main parts configuration of Small Laser Cutting Machine HSF-6040P

1.Adopt Japanese THK precision linear guide rail, with high positioning accuracy and less wear; it can maintain high precision for a long time, easy to assemble and interchangeable.

2.EtherCAT bus-type AheadTechs numerical control system (AheadTechs), which greatly improves the flexibility and scalability of the equipment. Make smart factories and equipment interconnection possible.

3.Support multiple modes of axis pitch compensation to ensure the machining accuracy of the machine tool.

4.Support parts processing statistics and production quantity management.

Technical details of small laser cutting machine :

| small laser cutting machine : | ||

| security function | laser unnormal alarm | yes |

| cutting unnormal alarm | yes | |

| gas low pressure alarm | yes | |

| door lock alarm | yes | |

| water chiler temperature unnormal alarm | yes | |

| Total power | 500w laser cutting machine | 11kw |

| 1000w laser cutting machine | 11kw | |

| Laser source | Fiber Laser | |

| Laser power | 500W/1000W | |

| Table size | 600x400mm | |

| Max speed | 1.2G | |

| Cooling way | water cooling | |

| Laser wavelength | 1070nm | |

| Min. cutting gap | ≤0.1mm | |

| Positioning accuracy of X, Y and Z axles | ±0.003 mm | |

| Repeated positioning accuracy of X, Y and Z axles | ±0.003 mm | |

| Working temperature | 5℃-45℃ | |

| Power requirement | 380V,50/60Hz(customized for you) | |

| Continuous working time | 24 Hours | |

Cutting Samples :