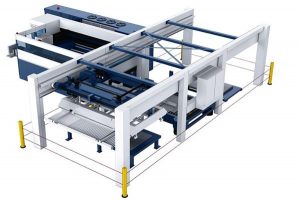

Application of stainless steel laser cutting machine in cabinet kitchenware industry

With the popularity of laser cutting machines and laser welding machines, the application of laser technology continues to penetrate into all walks of life, such as cabinets and stoves in our kitchens. In terms of kitchen design, in recent years, stainless steel and aluminum alloy materials are mostly used, which is very suitable for laser cutting machines for processing and manufacturing.

stainless steel laser cutting machine can play an important role in the production of kitchen and bathroom hardware products.

In recent years, many merchants who customize kitchen and bathroom products have begun to use laser cutting machines and laser welding machines. Laser cutting machine is used for cutting and blanking of steel plates. It has the characteristics of high cutting efficiency, high precision and high flexibility in processing. It is very prominently used in kitchen and bathroom hardware manufacturing. The laser welding machine is used for the splicing of various plates. Laser welding has the characteristics of small deformation, high efficiency and wide application, which has great advantages in mass production and processing.

In the manufacture of stainless steel cabinets, stainless steel laser cutting machine is widely used.

Laser cutting can avoid the burr problem of saw blade cutting, and it can be formed after one cutting. And the parts are cut out very accurately, reducing secondary processing or waste. The efficiency of laser cutting is 3-5 times faster than that of sawing. It is important to be able to adjust intelligently and flexibly. Products such as cabinets are often customized and tailored according to the customer’s kitchen. Then the laser equipment only needs to input the corresponding parameters to Easy access to various sheet metal parts. The precision of laser cutting is higher, making the corners and door seams of cabinets more precise and beautiful.

The current kitchen and bathroom hardware products are used by every household. Stainless steel cabinets, stainless steel cutlery, stainless steel sinks, steel stove racks, faucet showers, etc. are all suitable for laser cutting, and these thicknesses are usually in the 2- Generally, a 3000W stainless steel laser cutting machine can easily meet most of the large-scale manufacturers who have used stainless steel laser cutting machines for production. A device that can greatly improve processing efficiency and quality is believed to be able to serve more kitchen and bathroom hardware manufacturers. High-end manufacturing adds bricks and tiles.

Advantages of use stainless steel laser cutting machine.

It is very important that laser cutting process saves a lot of cost for enterprises. Because laser cutting does not require molds and knives, it greatly saves the cost of mold opening. Moreover, the labor cost will be greatly saved. What used to be done by ten people can now be done by one person.

Laser cutting technology satisfies the customized needs of the kitchen and bathroom products market well, with shorter production cycle, no need to make molds, reducing the time and cost of mold opening, no burrs on the processed surface, no secondary processing, and no problem after proofing Mass production can be achieved quickly.

Taking 304 and 306 stainless steel materials as an example, they are widely used in products such as range hood panels and gas appliance panels. The thickness is generally thin, within 3mm. Burrs do not require secondary processing, which increases the speed of processing and production several times….

As the price of stainless steel laser cutting machines becomes cheaper and cheaper, the application of laser technology in the stainless steel kitchenware industry is popularized faster.

Welcome to share more informations about the application knowledge of stainless steel laser cutting machine in the stainless steel kitchen and bathroom industry.